Sustainability

1. Focus on Renewable Energy

Headlands Distilling Co. integrates sources of renewable energy to power operations at the distillery. This helps us reduce our footprint when completing activities from heating the mash tun and still, powering the fermentation chiller, bottling machine, lights, computers and everything in between

2. Reusing Waste Heat

Our continuous distillation column is a unique energy efficient design, created in-house by the Headlands Distilling Co. team, saving up to 80%+ on power use. In contrast, pot stills and batch distillation processes are incredibly energy inefficient.

Say a distillery has a 1,000 litre pot still. After fermentation, the batch is around 7% alcohol. The distiller heats the 1,000 litre batch to boiling and distills off the alcohol, which at 7% alcohol is 70 litres of product. The distiller is left with 930 litres of boiling water which is lost down the drain. Not only is the water wasted, but the heat energy used to boil the water is also wasted. Pot stills also require cooling water for the condenser, or an electric chiller to cool the alcohol vapour. There are ways to get this heat back but it is often not done due to increased equipment and timing needed.

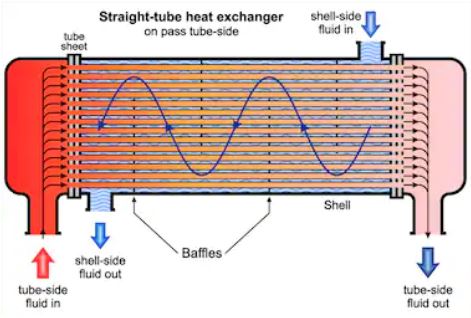

Our energy efficient continuous still pumps the 7% alcohol from fermentation through the outer shell of the condenser and is the injected into the distillation column. This has two benefits. The liquid is heated from ~20°C to 65°C for “free” (the liquid absorbs the heat from the vapour and condenses it) and we don’t need to waste any water to run the condenser. The fermentation liquid is its own cooling fluid.

The water leaving the base of our distillation column is further heat exchanged with the incoming 7% fermentation liquid, further scavenging waste heat energy. Any waste heat which isn’t recovered in this step is conserved by using this warm water to rinse our grains.

3. $5 Bottle Return Program

Each of our 700 mL bottles can be returned to us at markets, food and wine festivals, participating bottle shops or the distillery for a $5 credit on further purchases. These bottles are then sterilised and reused as part of our recycled bottle program.

Even if glass bottles are recycled by council (which they often are not, being put straight into landfill in Australia), it still takes lots of energy to transport the bins, sort, melt and finally blow mould into new bottles. Returning the bottle short circuits this process for maximum environmental benefits.

Bars and restaurants also return bottles for $5 off their next purchase.

4. No Single Use Plastic Seals

Most distilleries use heat shrink plastic to seal their bottles. The first thing a customer does, is rip this off and throw it in the bin. Therefore, this seal ends up directly in landfill.

At Headlands Distilling Co., we only use aluminium seals or a wax top seal – never single use plastic film.

5. Glass Tasting Cups

If you’ve visited us at a food festival, market, or the distillery, you will notice that we never serve product samples in small disposable plastic cups. Instead, we use small glass laboratory beakers. Rather than throwing plastic cups in the bin, we wash the glass beakers and can reuse them. Glass also preserves the flavour of the liquid and is much better for the environment!

If we serve full size drinks at food festivals, such as a delicious Boobialla gin and tonic, we serve only in uncoated biodegradable paper cups. Never a single use plastic cup.

6. By-Products to Local Farmers and Restaurants

Spent grain husks and yeast are provided for free to local farmers.

Spent Illawarra Plum skins, after 9 months of barrel ageing, are given to local fine dining restaurants such as Caveau, who transforms them into an Australian native gelato as well as other delicious dishes.

This promotes the circular economy where our waste is used as inputs by a downstream partner.

7. Planting Native Trees

Since we hand forage a large portion of the Illawarra Plum fruit, we save all the seeds and plant them. We have thousands of seeds and are continuously planting them. It is our ambition to have a whole Illawarra Plum tree orchard somewhere near Wollongong. We have meticulously logged the location where each seed was harvested, different Illawarra Plum trees fruit at vastly different times and have slightly different flavour. One strain we have growing finishes fruiting 2 months before others, allowing for a staggered and sustained fresh harvest!